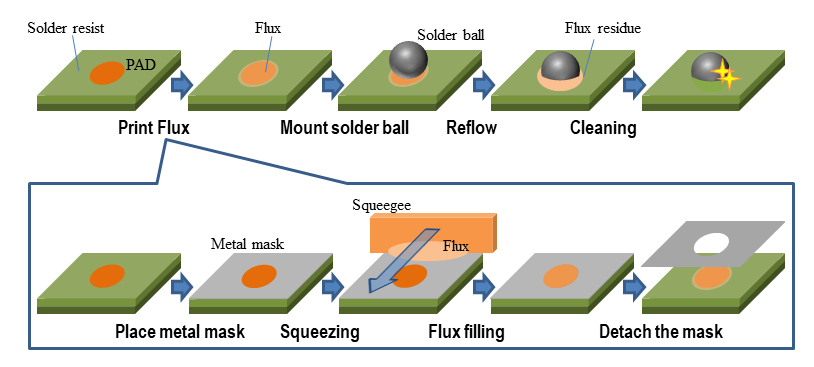

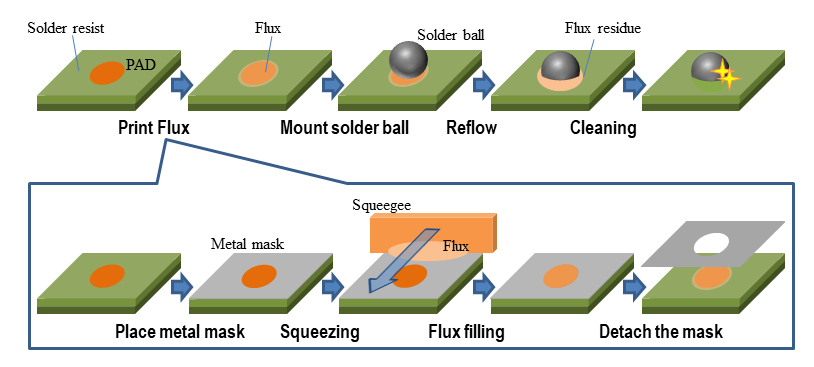

- Printing

- Summary

- Print a specified amount of flux at a designed location on the substrate

using a metal mask and squeegee.

Conditon

- The main setting conditions of a printing machine are as follows:

a. Squeegee material/hardness

b. Printing pressure (squeegee pressure)

c. Printing speed

d. Printing distance

e. Metal mask detach speed

f. Clearance (between substrate and metal mask)

g. Tact (printing time per substrate)

- The viscosity and thixotropic index as flux properties are related to

printing results.

Process

a. Place the metal mask at the specified location on the substrate.

b. Place the flux on the metal mask.

c. Fill the flux into the metal mask opening using squeegee.

d. Remove the metal mask from the substrate.

- Ball mount

- Summary

- Place the solder ball in place with the flux printed on it.

Condition

- There are 2 ways. 1 Place the ball with ball mounter. 2 Drop the ball

into the opening of metal mask.

Process (ball mounter)

a.Set substrate at specified place and set solder ball at supply unit.

b.Pick up solder ball by the nozzle of mounter.

c.Place solder ball at specified place where flux is already printed.

- Reflow

- Summary

- Joint solder ball to substrate with heating by "Reflow" soldering

equipment.

Condition

- Main reflow conditions are as follows,

a. Ambiance in Reflow eqipment (Usual air, (Nitrogen ex. Oxygen 1000ppm

and below ))

b. Temperature ramp up rate

c. Preheat temperature and time

d. Peak temperature

e. Keep time above solder melting temperature

f. Temperature cooling rate

Conveyor speed and temperature setting of each zone should be determined

in order to adjust above condition (from a to f).

Process

a. Set each parameter of Reflow and start heating.

b. Place substrate into the Reflow equipment after the inside temperature

has consistent.

- Cleaning

- Summary

- Flux residue after reflow is cleaned and completely removed.

Condition

- Main cleaning conditions are as follows,

a. Type of cleaning

b. Cleaning time

c. Type of cleaning agent

d. Cleaning temperature

Process

- Despite the different types of cleaning methods are available, the basic

flow is as follows.

( see ARATTE)

a. Clean substrate with cleaning agent.

b. Rinse substrate with rinse agent.

c. Dry

-