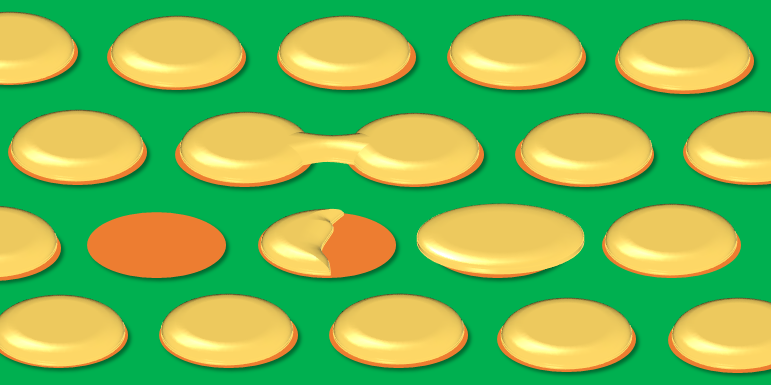

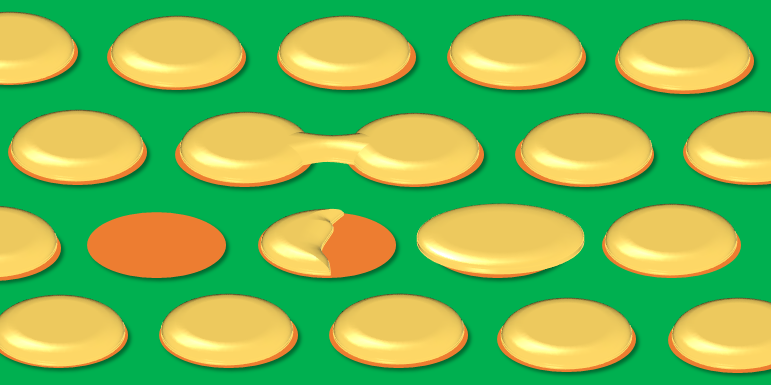

- Flux print failure

- Condition

- Insufficient volume, unfilled or bridging during soldering.

Primary cause

- Physical Properties of Flux

Viscosity is the main physical property that affects printability.

If the viscosity is too low, the flux tends to bleed easily and cause bridging.

On the other hand, too high viscosity makes it difficult to fill the printing

area with flux, and lacking and unfilled areas are likely to occur.

-Printing Conditions

Printing conditions include squeegee material, squeegee angle, printing

pressure, printing speed, metal mask shape, clearance between substrate

and metal mask, and their separation speed.

It is necessary to optimize the conditions for both substrate and flux.

- Solution

Optimize the printing conditions.

Consider applying Arakawa flux fitting as the ideal properties.

-