- Background

- When solder balls were mounted with the current flux, wrinkling and other wetting defects occurred on the solder ball surface. There were concerns about ball height variation and poor junction.

- Solution

- In developing the flux, we formulated a sufficient amount of components that would stay on the ball surface in order to prevent the flux flowing off the solder balls surface during reflow.

- Effectiveness

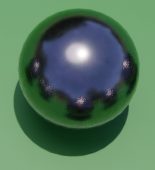

- The flux stayed on the ball surface during reflow process, which improved wrinkling and other wetting defects.

- Product

- WHP-121

- Solder ball surface with current flux with WHP-121

( Images are for illustrative purposes only. )